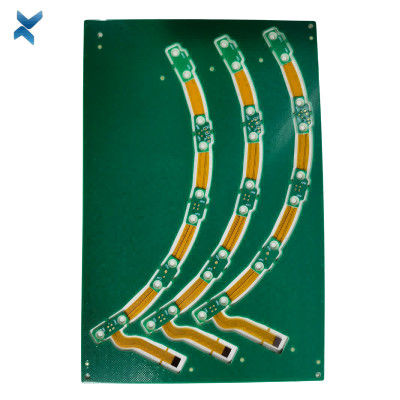

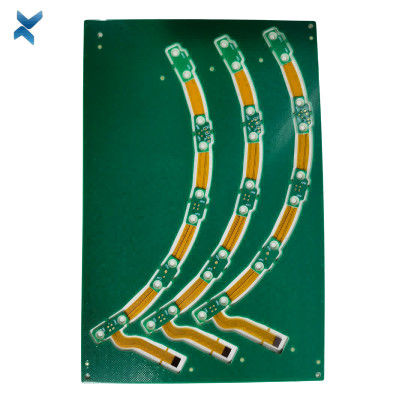

FR4 FPC Lead Free Printed Circuit Boards For Drug Delivery Systems

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Drug Delivery Systems PCB | Material | FR4-FPC |

|---|---|---|---|

| Surface Process | Immersion Gold | Size | 10*20cm |

| Thickness | 1.2mm | Layer | 6 Layers |

| Copper Thickness | 1.2 Oz | Application | Drug Delivery Systems |

| High Light | FR4 FPC Lead Free Printed Circuit Boards,FR4 FPC Rigid Flex Board,FR4 FPC Flexible Circuit Board |

||

FR4 FPC Lead Free Printed Circuit Boards For Drug Delivery Systems

Rigid Flex PCB Lead-Free Printed Circuit Boards For Drug Delivery Systems

Rigid-Flex PCBs

Rigid-flex PCBs is a complicated product that demands a lot of interaction between our and your technicians.

Like other complex products, early discussions between YScircuit and the designer is necessary to optimize the design for manufacturability and to optimize costs.

We support rigid-flex pcbs both locally in Europe and US as well as offshore for higher volume requirements.

Available structures for rigid flex PCBs

There are numerous, different structures available.

The more common ones are defined below:

Traditional rigid flex construction (IPC-6013 type 4) Multilayer rigid and flexible circuit combination containing three or more layers with plated through holes.

Capability is 22L with 10L flex layers.

Asymmetrical rigid flex construction, where the FPC is situated on the outer layer of the rigid construction.

Containing three or more layers with plated through holes.

Multilayer rigid flex construction with buried / blind via (microvia) as part of the rigid construction.

2 layers of microvia are achievable.

Construction may also include two rigid structures as part of a homogeneous build.

Capability is 2+n+2 HDI structure.

| YScircuit Rigid Flex PCB manufacturing capabilities overview |

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

FQA

Q: What is the Largest PCB I can have?

A: We make panels to suit your requirements, ranging from 5mm square through to 450 x 300mm (18 x 12 inches), which is the largest PCB size we can produce in-house, as standard, which has a useable area of 17 x 11 inches.

With more than 10 years’ experience designing and manufacturing PCB boards, we have discovered that the optimal size for our production is 450 x 300mm (18 x 12 inches) which can be a single circuit, or a step and repeated smaller circuit to fit the panel.

There are a number of factors to consider when developing a PCB board that include product size, single sided, double sided plated through hole or multilayer, as well as number and weight of components. Larger boards are developed with our reliable partners, with whom we have built a strong relationship over the years.

For more advice about PCB size, please call us any time.