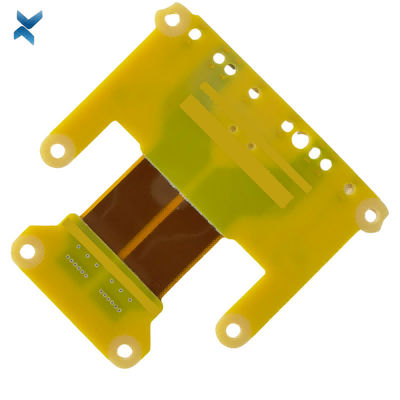

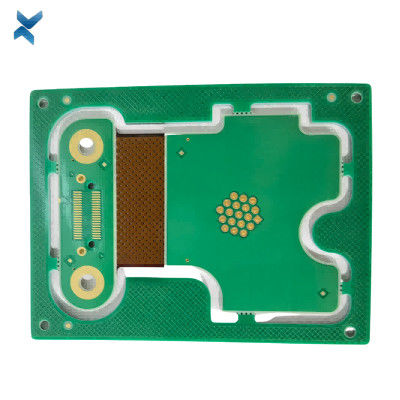

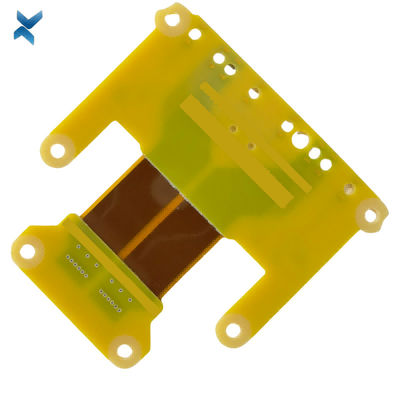

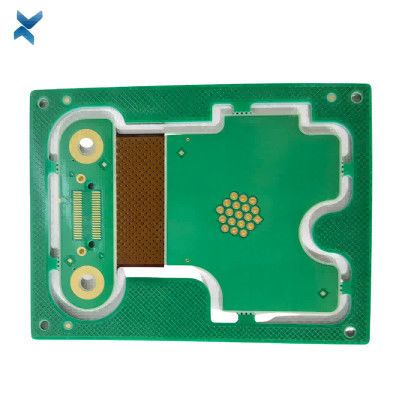

FR4 Flex Printed Circuit Boards Rigid Polymide PCB For E Toy

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | YS-0033 |

| Minimum Order Quantity | 1 piece |

| Price | 0.03-6$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | FR4, Polymide | Size | 10*6cm |

|---|---|---|---|

| Process | Immersion Gold | Surface Finishing | HASL/HASL-LF/ENIG |

| Min. Line Width | 3mi | Board Thickness | 1.2mm |

| Color | Yellow | Name | E-toys PCB |

| High Light | FR4 Flex Printed Circuit Boards,Flex Rigid Polymide PCB,E Toy Rigid Polymide PCB |

||

Rigid-Flex Printed Circuit Boards FR4 Polymide PCB For E-Toy

Introducing Rigid-Flex PCB Solutions

Rigid-flex PCBs are the perfect solution for devices that require both rigid and flexible substrates for their construction. With a combination of rigid fiberglass and flexible plastic substrates, these PCBs offer superior flexibility and durability.

Our rigid-flex PCBs are customizable to suit a variety of design requirements. At YScircuit, we offer a range of design elements to choose from, such as base materials, rolled or annealed copper, adhesive or adhesiveless core, coverlay or soldermask, static or dynamic flex, and coating options.

Our professional team at YScircuit will ensure that your fabrication job is completed to the highest standard.

YS Rigid Flex PCB manufacturing capabilities overview

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

![]()

![]()

![]()

![]()

![]()

FQA

1. What is a rigid-flex PCB?

A: A rigid-flex PCB is a printed circuit board that consists of both rigid and flexible areas. The rigid areas provide support and stability while the flexible areas allow the board to bend or flex.

2. What are the advantages of using a rigid-flex PCB?

A: Rigid-flex PCBs offer several advantages over traditional PCBs, including reduced size and weight, improved reliability, and increased design flexibility.

3. What are the design considerations for rigid-flex PCBs?

A: Designers must take into account the flexing and bending of the board when designing a rigid-flex PCB. They must also consider the placement and routing of components, as well as the location of any connectors or through-holes.

4. What are the materials used in rigid-flex PCBs?

A: The materials used in rigid-flex PCBs include copper, polyimide, and adhesive. Copper is used for the conductive traces, while polyimide is used for the flexible areas. Adhesive is used to bond the rigid and flexible areas together.

5. How are rigid-flex PCBs manufactured?

A: Rigid-flex PCBs are manufactured using a combination of traditional PCB fabrication techniques and specialized processes for the flexible areas. The rigid areas are typically fabricated using standard PCB techniques, while the flexible areas are created using specialized processes such as laser drilling or chemical etching.