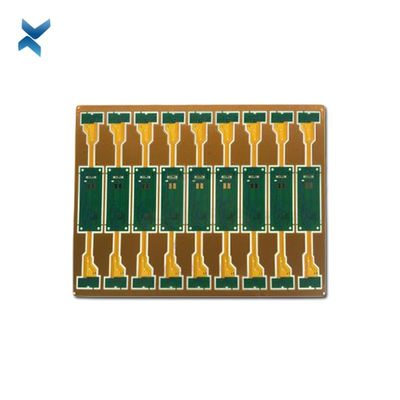

Wireless Controllers Rigid Flex PCB Prototype Copper Thickness 1oz

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Wireless Controllers PCB | Material | FR4-FPC |

|---|---|---|---|

| Surface Process | Immersion Gold | Size | 16*4cm |

| Thickness | 0.6mm | Layer | 2 Layers |

| Copper Thickness | 1 Oz | Application | Wireless Controllers |

| High Light | 1oz Rigid Flex PCB Prototype,0.6mm Flex PCB Circuit Boards,1oz Flexible Printed Circuit Board |

||

Wireless Controllers Rigid Flex PCB Prototype Copper Thickness 1oz

Rigid Flex PCB Prototype Circuit Boards For Wireless Controllers

Rigid Flex Printed Circuit Boards:

Rigid-Flex PCB are products using a combination of flexible and rigid board technologies in one application.

Depending upon the design of the application, rigid flex PCB's typically consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending upon the design of the application.

The flexible substrates are designed to be in a constant state of flex and are usually formed into the flexed curve during manufacturing or installation.

Flex Printed Circuit Boards:

By definition a Flex PCB is a patterned arrangement of printed circuitry and components that utilizes flexible based material with or without flexible coverlay.

These flexible electronic assemblies may be fabricated using the same components used for rigid printed circuit boards, but allowing the board to conform to a desired shape (flex) during its application.

Flex and Rigid Flex PCB Applications:

Rigid-Flex PCB are products using a combination of flexible and rigid board technologies in one application.

Depending upon the design of the application, rigid flex PCB's typically consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending upon the design of the application.

The flexible substrates are designed to be in a constant state of flex and are usually formed into the flexed curve during manufacturing or installation.

Rigid-flex circuitry provides a simple means to integrate multiple PCB assemblies and other elements such as display, input or storage devices without wires, cables or connectors, replacing them with thin, light composites that integrate wiring in ultra-thin, flexible ribbons between sections.

In rigid-flex packaging, a flexible circuit substrate provides a backbone of wiring with rigid multiplayer circuit sections built-up as modules where needed.

Flex PCBs are used widely in everyday technology and electronics in addition to high-end, complex completed components.

Two of the most prominent examples of flexible circuit usage is in modern portable electronics, devices, hard disk drives and desktop printers.

Flexible circuits are also used extensively in other applications and industries including: Communications , Industrial, consume electronics, aerospace, military, medical, and transportation.

| YScircuit Rigid Flex PCB manufacturing capabilities overview |

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

FQA

Q: Do you offer a variety of PCB finishes?

A: The substrate itself is coloured by pigment in the epoxy resin, which is used together with glass-fibre reinforcement to make up the finished board, which sits beneath the copper tracks. Our standard range of PCB colours is available for immediate manufacture, however, if you have a requirement for a specific colour, please contact us.

Q: How will my PCB order be packaged?

A: Our PCBs are vacuum sealed and generously wrapped ensuring protection during shipping.

Q: What delivery service do you use?

A: We use multiple services, mainly UPS and FedEx.

Q: What materials do you use to manufacture PCBs?

A: We use multiple materials, such as FR4, Aluminium, Cooper Base, Rogers, Isola and many more.

Q: Can you source specific materials?

A: Yes we can source most materials.