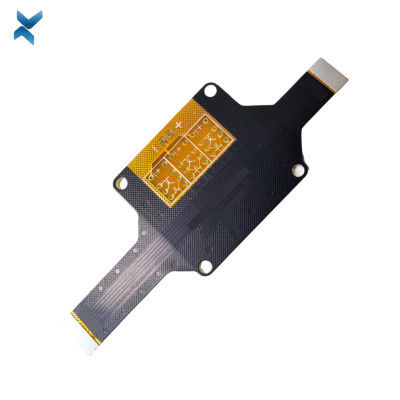

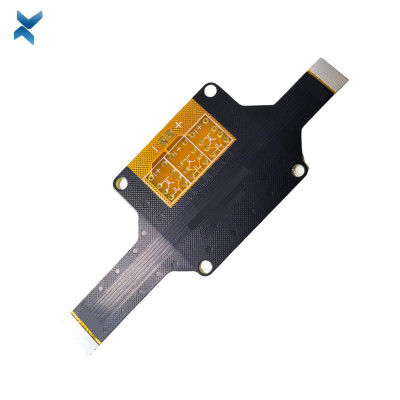

Gold Flashed Rigid Flex PCB Board 2 layers For Imaging Equipment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Imaging Equipment PCB | Material | FR4-FPC |

|---|---|---|---|

| Surface Process | Immersion Gold | Size | 14*4.2cm |

| Thickness | 0.8mm | Layer | 2 Layers |

| Copper Thickness | 1oz | Application | Imaging Equipment |

| High Light | Gold Flashed Rigid Flex PCB Board,0.8mm Rigid Flex PCB Board,1oz Rigid Printed Circuit Boards |

||

Gold Flashed Rigid Flex PCB Board 2 layers For Imaging Equipment

Rigid Flex PCB Gold Flashed Printed Circuit Boards For Imaging Equipment

What is a Rigid-Flex PCB?

A Rigid-Flex PCB is a hybrid circuit board combining elements of both flexible circuit boards and rigid circuit boards, with an end result of a board that is able to be folded or continuously flexed and is normally formed into a flexed shape or curve during the manufacturing process.

The flexible layers of a Rigid-Flex PCB are buried within the board and penetrate through the rigid sections of the PCB.

Rigid-Flex design

The designs of Rigid-Flex PCBs are a little more complex as these boards are designed in 3D, which allows the board to be folded or twisted to create the desired shape for the product. Designing a board in 3D means they can offer greater spatial efficiency and can subsequently be used in special instances where space and weight reduction may be necessary, such as in medical devices.

Rigid-Flex PCBs are usually thinner than other boards, meaning it’s a great option for any thin or light packaging needs your products may have. With thin copper layers and adhesive-less laminates, it’s a great small, thin and light solution for your circuit design needs.

Flex to install & dynamic flex PCBs

There are two common types of Rigid-Flex PCBs; flex to install and dynamic flex.

Flex to install: this is the most common of the two and applies when a board only folds once, either when the device or product is assembled or dismantled, but is otherwise sturdy and stable throughout.

Dynamic flex: a dynamic flex board will be used when a product is required to fold and bend when in use, meaning they are highly durable and can last through a thousand flex cycles.

Whilst the design might be a touch more complex, and the process slightly more time consuming than the usual printed circuit board, they are an investment worth making with their versatile and durable nature.

Rigid-Flex benefits

There are several benefits to a Rigid-Flex PCB which could make it a perfect choice for your product, including:

Reduced space requirement through 3D ability.

Shock resistance: Rigid-Flex PCBs can withstand high-stress environments.

Increased reliability: due to the reduced need for solder joints or connectors, Rigid-Flex PCBs are a brilliant choice for products where a connector or cable failure could be detrimental.

Rigid-Flex PCBs also have a simpler assembly process as they have fewer cables and connectors being used throughout.

If your product requires a board that needs to be folded when assembled or you’re after something highly durable and long-lasting then a Rigid-Flex PCB might be the right fit for you.

| YScircuit Rigid Flex PCB manufacturing capabilities overview |

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

FQA

Q: If I need the same PCBs in the future do I need to resend the data?

A: No, you don’t. We safely and securely retain your PCB information on record. This includes various revisions.

Q: How do you test the PCBs?

A: We use a state of the art flying probe tester, more than 3 square meter use E-testing.

Q: How should PCBs be stored to maximise shelf life?

A: PCBs should be vacuum sealed and stored in a dark dry location at room temperature.

Q: Can you do complex curved outlines on your printed circuit boards?

A: The substrate itself is coloured by pigment in the epoxy resin, which is used together with glass-fibre reinforcement to make up the finished board, which sits beneath the copper tracks.

Our standard range of PCB colours is available for immediate manufacture, however, if you have a requirement for a specific colour, please contact us.

Q: Can I have my printed circuit boards left in a panel for assembly?

A: The substrate itself is coloured by pigment in the epoxy resin, which is used together with glass-fibre reinforcement to make up the finished board, which sits beneath the copper tracks. Our standard range of PCB colours is available for immediate manufacture, however, if you have a requirement for a specific colour, please contact us.