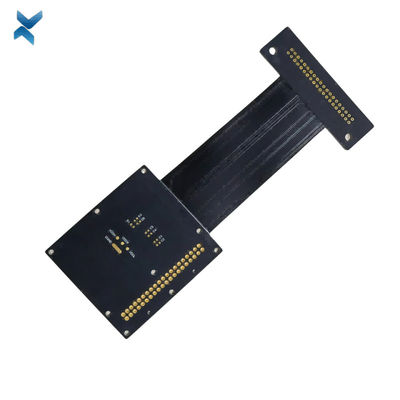

FR4 / Polymide Rigid Flex PCB Board Immersion Gold For Toy Plane

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | YS-0034 |

| Minimum Order Quantity | 1 piece |

| Price | 0.02-1.98$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | FR4, Polymide | Size | 8*4.8cm |

|---|---|---|---|

| Process | Immersion Gold | Surface Finishing | HASL/HASL-LF/ENIG |

| Min. Line Width | 3mi | Board Thickness | 1.2mm |

| Color | Black Yellow | Name | Toy Plane PCB |

| High Light | Toy Plane Rigid Flex PCB Board,Immersion Gold Rigid Flex PCB Board,Toy Plane Rigid Flex Boards |

||

Revolutionize Your Electronics With Rigid-Flex Boards For Toy Plane

Revolutionize Your Device with Rigid-Flex PCBs

Say goodbye to the limitations of traditional printed circuit boards and hello to the flexibility and durability of rigid-flex PCBs. Our PCBs use a combination of rigid fiberglass and flexible plastic substrates to offer a seamless construction that can bend around the corners of your device.

Our rigid-flex PCBs are highly customizable, with a variety of design options to choose from, such as base materials, rolled or annealed copper, adhesive or adhesiveless core, coverlay or soldermask, static or dynamic flex, and coating options.

Let our professional team at YScircuit handle the fabrication job and watch your device come to life like never before.

YSCircuit Rigid Flex PCB manufacturing capabilities overview

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

![]()

![]()

![]()

![]()

![]()

FQA

What are the testing methods for rigid-flex PCBs?

A: Testing methods for rigid-flex PCBs include visual inspection, electrical testing, and flex testing. Visual inspection is used to check for any physical defects or damage. Electrical testing checks for continuity and shorts. Flex testing involves bending and flexing the board to ensure that it can withstand the intended use.

What are the applications of rigid-flex PCBs?

A: Rigid-flex PCBs are used in a variety of applications, including aerospace, medical devices, consumer electronics, and automotive. They are ideal for applications that require compact, lightweight, and reliable electronics.

What are the cost considerations for rigid-flex PCBs?

A: Rigid-flex PCBs can be more expensive than traditional PCBs due to the specialized manufacturing processes and materials used. However, the cost may be offset by the benefits of reduced size and weight, improved reliability, and increased design flexibility.

What are the common problems encountered with rigid-flex PCBs?

A: Common problems with rigid-flex PCBs include delamination, cracking, and failure due to repeated flexing. These problems can be minimized through proper design, manufacturing, and testing.

What are the best practices for designing and manufacturing rigid-flex PCBs?

A: Best practices for designing and manufacturing rigid-flex PCBs include careful consideration of the intended use and environment, proper selection of materials and processes, thorough testing and inspection, and collaboration between the design and manufacturing teams.