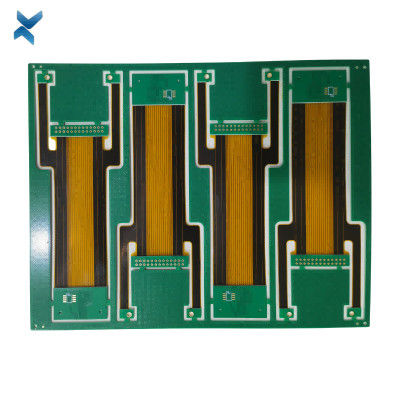

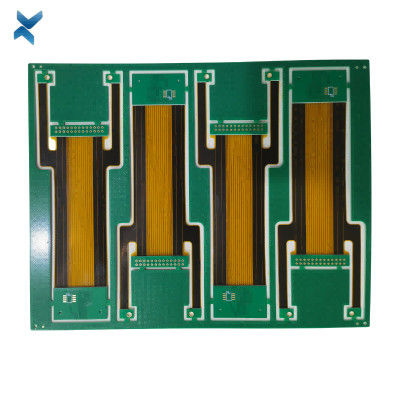

Custom Multilayer Rigid Flex PCB Board For Medical Stimulator

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | YS-0035 |

| Minimum Order Quantity | 1 piece |

| Price | 0.03-6$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | FR4 | Size | According To Customer Request |

|---|---|---|---|

| Process | Immersion Gold/sliver | Surface Finishing | HASL/HASL-LF/ENIG |

| Min. Line Width | 0.1mm | Base Material | FR-4 |

| High Light | Multilayer Rigid Flex PCB Board,Custom Rigid Flex PCB Board,Medical custom flex pcb |

||

Multilayer PCB Board Prototype Custom Printed Circuits Rigid Flex PCB Manufacturer

What is a Rigid Flex PCB?

Rigid-Flex printed circuit boards are boards using a combination of flexible and rigid board technologies in an application.

The proper application of Rigid-Flex circuit boards offers optimum solutions for difficult, limited space conditions. This technology offers the possibility of a secure connection of device components with the assurance of polarity and contact stability, as well as a reduction in plug and connector components.

Additional advantages of Rigid-Flex circuit boards are dynamic and mechanical stability, the resulting 3-dimensional freedom of design, simplified installation, space savings, and maintenance of uniform electrical characteristics.

Rigid-Flex circuit boards are composed of a combination of rigid and flexible circuit boards that are permanently connected to one another.

Parameters

Layers: 8L rigid flex pcb

Board Thinkness:0.69mm+/-0.1mm

PCB thickness in flex section:0.5mm+/-0.05mm

Base Material:PI+FR4pp

Min laser Holes:0.075mm(3mil)

Min mechanical Holes:0.15mm

Minimum Line Width/Clearance:0.046mm/0.046mm( 1.8mil/1.8mil)

Minimum Clearance between Inner Layer PTH and Line: 0.175mm

Size:160.92mm×145mm

Aspect Ratio:4.6 : 1

Surface treatment:ENIG

Speciality: rigid flex pcb multilayer fpc HDI Any-Layer PCBs stacked vias, Fine circuit 1.8mil, High Density Interconnect PCB 1.8mil/1.8mil,Laser via copper plated shut

Differential impedance 100+7/-8Ω

Applications: Medical stimulator

YS Rigid Flex PCB manufacturing capabilities overview

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds |

|

![]()

![]()

![]()

![]()

![]()

FQA

1. Do you offer double-layer flexible PCB?

Yes, we make single layer flexible PCB, double sided flexible PCB, multi-layer flexible PCB, and Rigid-Flex PCBs.

2. Do you provide stiffeners and cover films?

Yes, we provide black PI stiffeners, yellow PI cover films, transparent polyimide films, white overlay, and brown PI copper clad laminates.

3. Do you use adhesive free copper foil base material?

Yes. We have four manufacturing methods for adhesive-free copper foil base materials. We use spray plating, curtain coating, electroless deposition/electrolytic plating, and laminating.

4. What are the minimum and maximum thickness of your adhesive flex PCBs?

Minimum thickness is 2 µm and the maximum is 200 µm.

We ensure high chemical durability and processing compatibility for flexible printed circuits and do not sacrifice its original electrical property, heat-resistant property, and mechanical property.

5. Which IPC standards do you follow?

IPC Standards for Rigid and Flexible PCBs

The list of IPC standards below applies to rigid PCBs and flex circuits. Take note that this list is not exhaustive, and additional IPC standards may need to be considered.

You should consult the ipc.org website for a full list of available IPC standards.