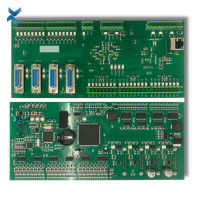

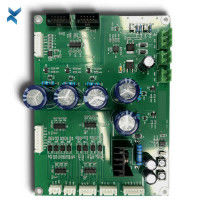

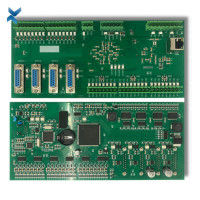

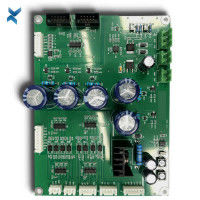

Immersion Tin PCBA Circuit Board Assembly For Industrial Applications

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | YS-PCBA-0021 |

| Minimum Order Quantity | 1 piece |

| Price | 0.17-9$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | FR4+Component Parts | Size | 28*12cm |

|---|---|---|---|

| Process | Immersion Tin | Surface Finishing | HASL/HASL-LF/ENIG/OSP |

| Product Name | Industrial Applications PCBA | Application | Industrial Applications |

| Base Material | FR-4 | Copper Thickness | 2OZ |

| High Light | 2OZ PCBA Circuit Board Assembly,Immersion Tin PCBA Board Assembly,28*12cm PCBA Board Assembly |

||

PCBA High-Quality PCB Assembly For Industrial Applications

What exactly does PCBA stand for?

It's the acronym for Printed Circuit Board Assembly, which involves the process of assembling various electronic components onto a circuit board using a surface mounting technique.

The next step is the box assembly, where the completed PCB is combined with an outer casing to create the final product.

Essentially, PCBA refers to the entire process of SMT assembly and DIP insertion of the PCB.

This method is commonly used in China, while in Europe and America, it's referred to as PCB'A, with an added diagonal punctuation mark.

When developing a new electronic design, it's typical to create a prototype PCB assembly, or a sample PCBA, to validate the design before making any updates and moving on to mass production if the market conditions are favorable.![]()

| Capability | Standard |

| Certifications: | ISO 9001: 2015, AS 9100 Rev D, ISO 13485: 2016 |

| Lead Time: | 1-5 Days, As per the scheduled period |

| Parts procurement: | Full Turnkey, Partial Turnkey, and Knitted |

| Assembly Types: | Surface Mount (SMT), Thru-hole, Mixed Technology, Single and double-sided SMT/PTH. |

| Stencils: | Laser cut stainless steel and Nano-coating |

| Components: | Passive components smallest size 0201, Fine pitch components smallest size 8 Mils pitch. |

| Component packaging: | Reels, Cut Tape, Tube, and lose parts. |

| Inspection: | X-ray analysis, AOI, and Microscope to 20X |

| Solder Type: | Leaded and Lead-free/ RoHS compliant |

| Assembly Surface mount connectors: | Yes |

| Wave Soldering: | Yes |

| PCB Finish: | SMOB/HASL, Electrolytic gold, Electroless gold, Electroless silver, Immersion gold, Immersion gold, Immersion tin, and OSP. |

| Panelized PCB: | Tab routed, Breakaway tabs, V-scored and Routed + V scored |

| Rework: | BGA removal and replacement station, SMT IR rework station, and Thru-hole reworks station. |

| Design file format: | Gerber RS-27, 274D, Eagle and Auto CAD's DXF, DWG BOM, and Pick and place a file |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

![]()

![]()

![]()

![]()

![]()

FQA

What is contract electronics manufacturing?

Contract electronics manufacturing refers to the practice of outsourcing the manufacturing of your product to a specialized electronics manufacturing facility.

These facilities exclusively work in the electronics manufacturing industry.

We can provide a range of services, including prototyping and new product development.

Others may specialize in areas such as PCB/PCBA, cable assembly, and wire harnessing.