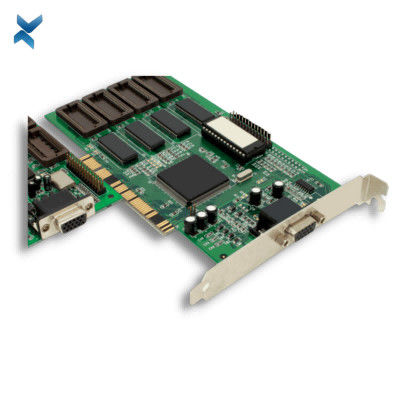

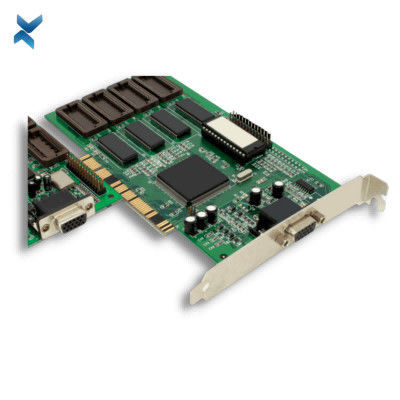

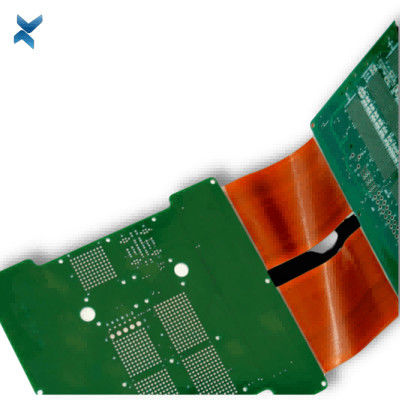

OEM Bare FR4 Base PCBA Circuit Board Assembly For LCD Displays

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | YS-PCBA-0018 |

| Minimum Order Quantity | 1 piece |

| Price | 0.17-9$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | FR4+Component Parts | Size | 42*30cm |

|---|---|---|---|

| Process | Immersion Gold | Surface Finishing | HASL/HASL-LF/ENIG/OSP |

| Product Name | LCD Displays PCBA | Application | LCD Displays |

| Base Material | FR-4 | Copper Thickness | 1.5OZ |

| High Light | FR4 Base PCBA Circuit Board Assembly,1.5OZ PCBA Circuit Board Assembly,FR4 Bare Circuit Board |

||

OEM Bare FR4 Base PCBA Circuit Board Assembly For LCD Displays

Industry PCBA Assembly OEM Bare Circuit Board For LCD Displays

What Is PCBA?

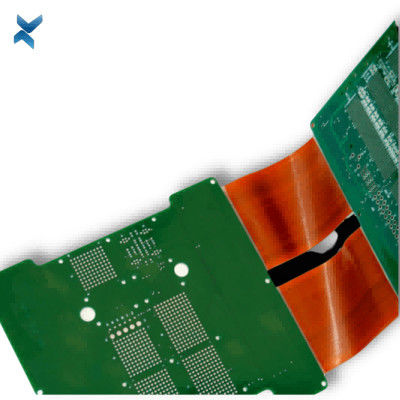

A PCB consists of non-insulating and heat-resistant materials.

It has a substrate that dissipates the heat to keep the entire setup cool and high-performing.

The upper section has conductive materials such as copper to transmit the signal electronically from one part to another.

The substrate is made of different elements and it works to dissipate heat.

However, the PCB is an incomplete construction as it doesn’t have the electronic components, not on it.

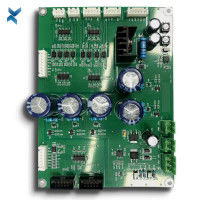

The PCBA, on the other end, is a complete assembly.

You have to assemble the PCB, once it is ready.

The assembling requires both passive and active components.

The list of these electronic components include-

Resistor

SMD capacitor

Transformer

Diode

ICs

Transmitter

You have to mount these components on the printed circuit board to prepare the fully usable circuit boards.

And this assembled circuit board is the PCBA we are referring to until now.

Also, note that the electronic components can be of two types.

These types are-

SMD components: It refers to surface mount devices.

You have to use the surface mount technology to install these components on the PCB.

You can identify the SMD components by measuring the number of pins in the package.

Through-hole components: Thru-hole or through-hole components have leads in them.

The leads are inserted through the PCB board surface.

You have to drill holes on the PCB surface to insert the thru-hole components into it.

The assembly of the printed circuit board is done in two ways.

You may opt for automated soldering to mount the electronic components on the PCB.

The most popular soldering technology is wave soldering.

It is used for the conventional thru-hole components.

Another widespread technology to solder the components on the PCB is the Reflow soldering technique.

It is used for SMD components mostly.

You may also use mixed soldering technology.

Some expert professionals will use hand soldering too.

But it is a quite difficult task.

When you complete the soldering or assembling of the electronic components on the printed circuit board, it is referred to as the PCBA or Printed Circuit Board Assembly.

Until you prepare the PCBA, the PCB isn’t ready for any application.

And when you have prepared the PCBA, you can use it for use on different devices.

|

Capability |

Standard |

|

Certifications: |

ISO 9001: 2015, AS 9100 Rev D, ISO 13485: 2016 |

|

Lead Time: |

1-5 Days, As per the scheduled period |

|

Parts procurement: |

Full Turnkey, Partial Turnkey, and Knitted |

|

Assembly Types: |

Surface Mount (SMT), Thru-hole, Mixed Technology, Single and double-sided SMT/PTH. |

|

Stencils: |

Laser cut stainless steel and Nano-coating |

|

Components: |

Passive components smallest size 0201, Fine pitch components smallest size 8 Mils pitch. |

|

Component packaging: |

Reels, Cut Tape, Tube, and lose parts. |

|

Inspection: |

X-ray analysis, AOI, and Microscope to 20X |

|

Solder Type: |

Leaded and Lead-free/ RoHS compliant |

|

Assembly Surface mount connectors: |

Yes |

|

Wave Soldering: |

Yes |

|

PCB Finish: |

SMOB/HASL, Electrolytic gold, Electroless gold, Electroless silver, Immersion gold, Immersion gold, Immersion tin, and OSP. |

|

Panelized PCB: |

Tab routed, Breakaway tabs, V-scored and Routed + V scored |

|

Rework: |

BGA removal and replacement station, SMT IR rework station, and Thru-hole reworks station. |

|

Design file format: |

Gerber RS-27, 274D, Eagle and Auto CAD's DXF, DWG BOM, and Pick and place a file |

|

layer/m² |

S<1㎡ |

S<3㎡ |

S<6㎡ |

S<10㎡ |

S<13㎡ |

S<16㎡ |

S<20㎡ |

S<30㎡ |

S<40㎡ |

S<50㎡ |

S<65㎡ |

S<85㎡ |

S<100㎡ |

|

1L |

4wds |

6wds |

7wds |

7wds |

9wds |

9wds |

10wds |

10wds |

10wds |

12wds |

14wds |

15wds |

16wds |

|

2L |

4wds |

6wds |

9wds |

9wds |

11wds |

12wds |

13wds |

13wds |

15wds |

15wds |

15wds |

15wds |

18wds |

|

4L |

6wds |

8wds |

12wds |

12wds |

14wds |

14wds |

14wds |

14wds |

15wds |

20wds |

25wds |

25wds |

28wds |

|

6L |

7wds |

9wds |

13wds |

13wds |

17wds |

18wds |

20wds |

22wds |

24wds |

25wds |

26wds |

28wds |

30wds |

|

8L |

9wds |

12wds |

15wds |

18wds |

20wds |

20wds |

22wds |

24wds |

26wds |

27wds |

28wds |

30wds |

30wds |

|

10L |

10wds |

13wds |

17wds |

18wds |

20wds |

20wds |

22wds |

24wds |

26wds |

27wds |

28wds |

30wds |

30wds |

|

12L |

10wds |

15wds |

17wds |

18wds |

20wds |

20wds |

22wds |

24wds |

26wds |

27wds |

28wds |

30wds |

30wds |

|

14L |

10wds |

16wds |

17wds |

18wds |

20wds |

20wds |

22wds |

24wds |

26wds |

27wds |

28wds |

30wds |

30wds |

|

16L |

10wds |

16wds |

17wds |

18wds |

20wds |

20wds |

22wds |

24wds |

26wds |

27wds |

28wds |

30wds |

30wds |

![]()

![]()

![]()

![]()

![]()

FQA

Q: Which kind of files are required for PCBA order?

A:

1) Gerber file, for PCB production.

2) BOM list file (Bill of Materials)..

3) CPL file (Component Placement List) or PNP file (Pick& Place File).

They’re used to determine the correct location on boards by automatic SMT Assembly machines.

Q: How about the smallest/largest size during assembly?

A:

1) On SMT Assembly machines:

Smallest size: 50*50mm

Largest size: 1200*460mm

2) Manual work: No limited.

Q: What are your requirements for the panelized board?

Please panelize your boards with stamp holes or V-cut.

A: The panelized size within the range of 100*100mm and 300*300m would be better.

Q: Do I need to add fiducial marks myself?

A:No, you don’t have to. We’ll add fiducial marks for SMT assembly.

Q: How do you define turn-time?

A:

Assembly turn-time begins as soon as PCB turn-time ends.

PCA orders can be finished within 24 hours.

The necessary materials for SMT assembly will be prepared (SMT engineering data, components and solder paste stencil, etc.) during PCB production, so that assembly can begin immediately after PCB fabrication completed.

Therefore, to accelerate production, please make your files clear, accurate and normative as far as possible.

Q: Is lead or lead-free assembly provided?

A: Both are available.