4mil Metal Core Multilayer PCB Prototype With FR4 Sheet Material

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Application | Product Name | Metal Core Pcb Circuit Board |

|---|---|---|---|

| Certificate | ISO9001 | Base Material | FR-4 |

| Min. Line Spacing | 4mil | Board Thickness | 1.6mm |

| Min. Line Width | 3mi | ||

| High Light | 4mil Multilayer PCB Prototype,FR4 Multilayer PCB Prototype |

||

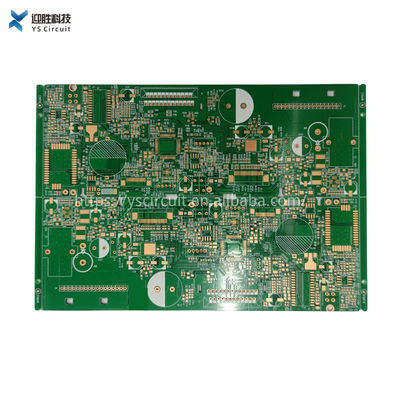

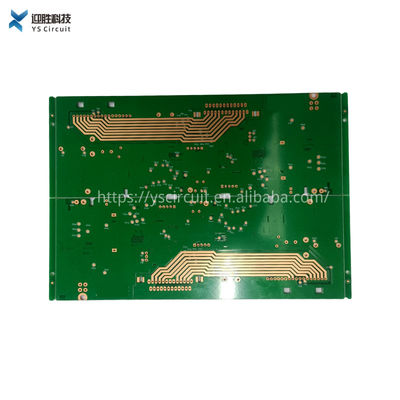

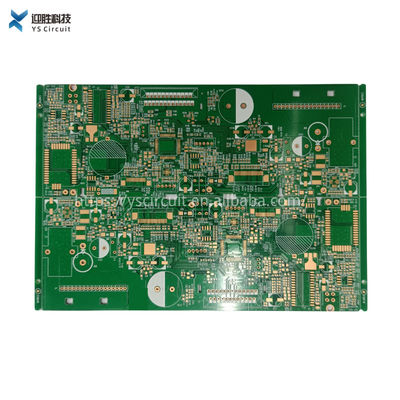

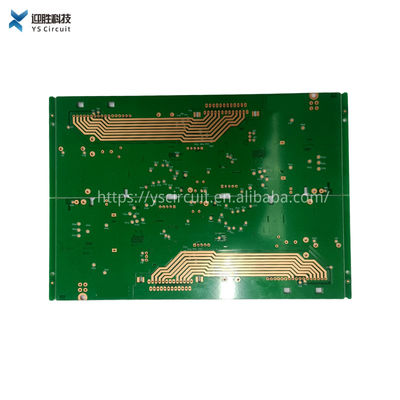

- Layers: 8L multilayer pcb

- Board Thinkness:2.0mm

- Base Material:S1000-2 High tg

- Min Holes:0.2mm

- Minimum Line Width/Clearance:0.25mm/0.25mm

- Minimum Clearance between Inner Layer PTH to Line: 0.2mm

- Size:250.6mm×180.5mm

- Aspect Ratio:10 : 1

- Surface treatment:ENIG+ Selective hard gold

- Process characteristics: High tg, Sideplating, Selective hard gold, Half-cut Castellated Holes

- Applications: Wi-Fi modules

| YS Multilayer PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 3-60L | |

| Available Multilayer PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 Mix etc. | |

| High Speed Material such as M7NE and FR4 Mix etc. | ||

| Thickness | 0.3mm-8mm | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, White, Black, Purple, Matte Black, Matte green.etc. | |

![]()

![]()

![]()

![]()

![]()

FQA

1. What is hard gold in PCB?

The Hard Gold surface finish, also known as Hard Electrolytic Gold, is composed of a layer of gold with added hardeners for increased durability, plated over a barrier coat of nickel using an electrolytic process.

2. What is hard gold plating?

Hard gold plating is a gold electrodeposit that has been alloyed with another element to alter the grain structure of the gold to achieve a harder deposit with a more refined grain structure.

3. What is the difference between Enig and hard gold?

ENIG plating is much softer than hard gold plating.

ENIG plating holds up well at only 35 grams of contact force or less, and ENIG plating typically lasts for fewer cycles than hard plating.

A popular trend among manufacturers is board-to-board soldering.

This technique allows companies to produce integrated modules (often containing dozens of parts) on a single board that can be built into another assembly during production.

One easy way to produce a PCB that is destined to be mounted to another PCB is to create castellated mounting holes.

These are also known as "castellated vias" or "castellations."