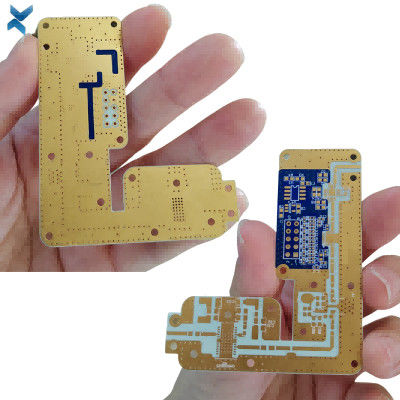

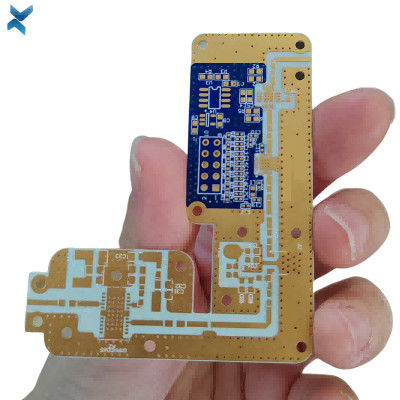

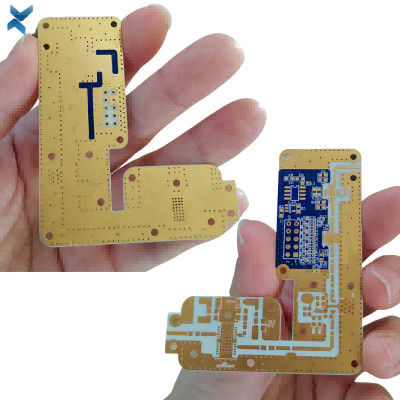

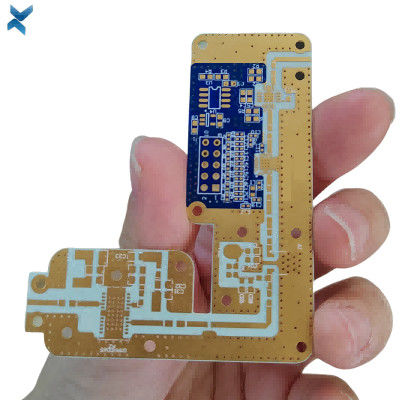

Aviation Rogers RO4350B PCB 4 Layers 0.2cm Immersion Gold Processing

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | RO4350B |

| Minimum Order Quantity | 1 piece |

| Price | 0.04-5$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | RO4350B | Size | 8.8*6.6cm |

|---|---|---|---|

| Process | Immersion Gold | Surface Finishing | HASL/HASL-LF/ENIG |

| Layer | 4 Layers | Thickness | 0.2cm |

| Application | Aviation | Name | Aviation Pcb |

| High Light | Aviation Rogers RO4350B PCB,4 Layers Rogers RO4350B PCB,Immersion Gold Rogers RO4350B PCB |

||

Rogers PCBs Lets Understanding The Basics Of Aviation

Rogers-pcbs

As a PCB fabrication. YScircuit PCB company offers Rogers PCBs boards from 1 layer to 30 layers. High multilayer Rogers circuit board fabrications. And we can produce the PCB boards with Buried and Blind Vias holes. The best smallest Buried and Blind Vias diameter are 3mil or 4mil. Most of the holes are the 4 mil size. And we have made many Rogers materials pcb with Hybrids & Mixed Dielectrics too. Maybe two or three differents kinds Rogers core materials. or other differents PCB core. Maybe FR4 or maybe High Performance materials. Like Isola or FR408HR.

There are many Rogers base core materials in our company’s warehouse. So, we can produce the the Rogers printed circuit board thickness from 0.15mm to 2.0 mm. Please see the Rogers boards materials in below list. If your PCB materials type are not in the list. Please check with our engineer. We will buy them in a short lead time.

Rogers PCB Impedance Control. The standard Impedance is +/-10%. We have made many this standard Impedance PCB with high quality. And our company also make the Impedance with +/-5%. It’s more accurate. The quality are Great! And about the Non‐Conductive Via Fill. If you need this request. We can do it well.

![]()

YScircuit Have Stock of Whole Series Rogers!!

| RO3000 series | Based on ceramic-filled PTFE circuit materials, the models are: RO3003, RO3006, RO3010, RO3035 high-frequency laminates. |

| RT6000 series | Based on ceramic-filled PTFE circuit materials, designed for electronic circuits and microwave circuits that require high dielectric constants. The models are: RT6006 dielectric constant 6.15, RT6010 dielectric constant 10.2. |

| TMM series | composite materials based on ceramics, hydrocarbons, and thermosetting polymers. The models are: TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, and many more. |

3001 Bonding Film (Thermoplastic Chloro-fluorocopolymer)

RO3000® series High-Frequency Laminates (PTFE/Ceramic)

RO3035® series High-Frequency Laminates (PTFE/Ceramic)

RO3200® series High-Frequency Laminates (PTFE/Ceramic)

RO4000® High-Frequency Laminate with TICER Foil

RO4000® laminates datasheet and fabrication guidelines: RO4003C, RO4350B

RO4400® prepreg datasheet and fabrication guidelines: RO4450B, RO4450F

RO4500® Antenna Grade Laminates for High Volume Applications

RT/duroid® 5870/5880 Glass Microfiber Reinforced PTFE Composites

RT/duroid® 6002 laminate datasheet

RT/duroid® 6006/6010 laminate datasheet

RT/duroid® 6202 laminate datasheet

RT/duroid® 6202PR laminate datasheet

TMM Thermoset laminate datasheet: TMM3, TMM4, TMM6, TMM10, TMM10i

ULTRALAM 2000 laminate datasheet

ULTRALAM 3000 LCP laminate datasheet: ULTRALAM 3850

ULTRALAM 3000 LCP Prepreg: ULTRALAM 3908

LONGLITE™ AND R/flex® Flexible Circuit Materials – Thin Dielectrics

LONGLITE™ Flex 200 Adhesiveless Materials

LONGLITE™ Flex 300 Adhesiveless Series

R/flex® 1000 Circuit Materials for Long-life Dynamic Flexing

R/flex® 1100 Circuit Materials – High-Temperature Laminates

R/flex® 1500 Assembly Adhesive

R/flex® 2001 Laminates and Coverfilms

R/flex® 2005 Laminates and Coverfilms

8080 Liquid Photoimageable Covercoat datasheet

8080 Liquid Photoimageable Covercoat: LP11

8080 Liquid Photoimageable Covercoat: LP2

R/flex CRYSTAL 7500 Laminates and Coverlayers

R/flex CRYSTAL 7700 Laminates and Coverlayers

R/flex JADE A coverfilm datasheet

R/flex JADE A laminates datasheet

R/flex JADE J coverfilm datasheet

R/flex JADE J laminate datasheet

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds |

|

![]()

![]()

![]()

![]()

![]()

FAQ

What do I need to focus on when you consider the mechanical and electrical properties of a Rogers printed circuit board?

Well, you should concentrate on the specific performance requirements.

It should include water absorption, thermal expansion, temperature stability, moisture absorption rate, and absorption percentage.

Final Thoughts

The type of material you decide to have on your printed circuit board proves a weighted subject.

It will determine plenty of aspects regarding its applicability in the preferred application areas.

You, therefore, have to get this right in the design phase before engaging a PCB manufacturer for its prototyping or production.

We hope that the information on this piece has enlightened you on the various aspects of Rogers PCB.