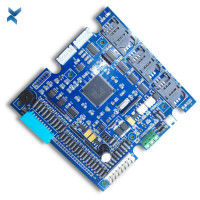

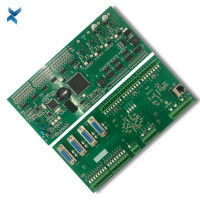

OEM Assembly PCB Quick Turn Immersion Gold For Lampblack Machine

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | YS-QT-0009 |

| Minimum Order Quantity | 1 piece |

| Price | 0.04-5$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | FR4+Component Parts | Size | 5*10cm |

|---|---|---|---|

| Process | Immersion Gold | Surface Finishing | HASL/HASL-LF/ENIG/OSP |

| Soldermark Color | Green | Copper | 1oz |

| Application | Lampblack Machine | Name | Lampblack Machine PCBA |

| High Light | Assembly PCB Quick Turn,OEM PCB Quick Turn,Immersion Gold quick turn pcba |

||

Quick Turn PCBA For Lampblack Machine OEM Assembly Print Circuit Boards

Quick turn PCBs

Quick turn PCBs refer to printed circuit boards (PCBs) that are fabricated and assembled very quickly, hence the name 'quick turn' PCB, and electronics manufacturers avail themselves of this method because it promises qualitative end products, as well as cost and time efficiency.

The rising demand for electronic devices and appliances translates into a huge, competitive market where large-scale production is necessary.

Quick turn makes it possible for manufacturers to stay on top of their game in both quantity and quality.

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 0-0.5m2 | 0.5-1m2 | 1-3m2 | 3-5m2 | 5-10m2 | |

| 1-2L | 24H | 24H | 3wds | 4wds | 5wds |

| 4L | 24H | 48H | 4wds | 5wds | 6wds |

| 6L | 48H | 48H | 4wds | 6wds | 6wds |

| 8L | 48H | 36H | 5wds | 6wds | 8wds |

![]()

| Technical index | Mass Batch | Small batch | Sample | ||

| Base Material | FR4 | Normal Tg | Shengyi S1141,KB6160(not suitable for lead free process) | ||

| Middle Tg | For HDI, multi layers: SY S1000H,ITEQIT158.TU-662 | ||||

| High Tg | For thick copper, high layer: SY S1000-2;ITEQIT180A;ISOLA:FR408R;370HR;TU-752; | ||||

| Halogen Free | Middle Tg:SYS1150G.H160HF;high Tg: SYS1165 | ||||

| High CTI | CTl≥600 SY S1600 | ||||

| High Frequency | Rogers,Arion,Taconic,SY SCGA-500.S7136 | ||||

| High Speed | SYS7439,TU-862HF.TU-872SLK;ISOLA:l-Speed.1-Tera@MT40; | ||||

| Flex Materia | Base | Glue-free:Dupont AK XingyangW-type,Panosonic RF-775; | |||

| Coverlay | SY SF305C.Xingyang O-type | ||||

| Special PP | No flow PP:VT-447LF.Taiguang 370BL Arion 49N | ||||

| Ceramic filled adhesive sheetRogers4450F | |||||

| PTFE adhesive sheetArion6700.Taconic FR-27/FR-28 | |||||

| Double-sided coating PExingyang N-1010TF-mb | |||||

| Metal Base | Berguist Al-base, chaosun Al-base,copperbase | ||||

| Special | High heat resistance rigidity Pl: TenghuiVT-901.Arion85N.SY S260(Tg250) | ||||

| High thermal conductivty material: 92ML | |||||

| Pure ceramic matenal: alumna ceramic.Aluminum nitride ceramics | |||||

| BT material: Taiwan Nanya NGP-200WT | |||||

| Layers | FR4 | 20 | 36 | 48 | |

| Rigid8Flex/(Flex) | 16(6) | 16(6) | 24(6) | ||

| High Frequency Mixed Lamination | 12 | 12 | 20 | ||

| 100% PTFE | 6 | 6 | 10 | ||

| HDI | 4 steps | 4 steps | 4 steps | ||

| Technical lndex | Mass Batch | Small Batch | Sample | ||

| Delivery Size | Max(mm) | 1200*560 | 1200*560 | 1200*560 | |

| (mm) | Min(mm) | 20*20 | 10"10 | 5*10 | |

| Finish board thickness | Max(mm) | 10 | |||

| Min(mm) | 0.3 | ||||

| Width/Gap | Inner(mil) | 0.5OZ base cooper: 3/3 1.0OZ base copper: 4/42.0OZ base copoer: 516 | |||

| 3.0OZ base cooper: 7/9 4.0OZ base copper: 8/12 5.0OZ base copper: 10/15 | |||||

| 6.0OZ basecooper: 12/18 10OZ basecopper: 18/24 12OZ base copper: 20/28 | |||||

| Outer (mil) | 1/3OZ base copper: 3/3 0.5OZ base copper: 4/4 1.0OZ base copper: 5/5 | ||||

| 2.0OZ base cooper: 6/8 3.0OZ base copper: 7/10 4.0OZ base copper: 8/13 | |||||

| 5.0OZ base cooper: 10/16 6.0OZ base copper: 12/18 10OZ base copper:18/24 | |||||

| 12OZ base copper: 20/28150Z base copper: 24/32 | |||||

| Line Width Tolerance |

>5.0 mil | ±20% | ±20% | ±1.0mil | |

| ≤5.0 mil | ±1.0mil | ±1.0mil | ±1.0mil | ||

| Drilling | Min laser(mm) | 0.1 | 0.1 | 0.1 | |

| Min CNC(mm) | 0.2 | 0.15 | 0.15 | ||

| Max CNC drill bit (mm) | 6.5 | 6.5 | 6.5 | ||

| Min Half Hole(mm) | 0.5 | 0.4 | 0.4 | ||

| PTH Hole(mm) | Normal | ±0.1 | ±0.075 | ±0.075 | |

| Pressing Hole | ±0.05 | ±0.05 | ±0.05 | ||

| Hole Angle(conical) | Width of upper diameters≤6.5mm:800,900,1000,1100:Width of upper diameters≤65mm:900; | ||||

| Frecision of Depth-control Drilling (mm) | ±0.10 | ±0.075 | ±0.05 | ||

| Number of blind CNC holes of one sidd | ≤2 | ≤3 | ≤4 | ||

| Minimum via hole spacing (different network, military, medical, automobile )mm | 0.5 | 0.45 | 0.4 | ||

| Minimum via spacing(different network, general industrial control and consumer electronic ) mm | 0.4 | 0.35 | 0.3 | ||

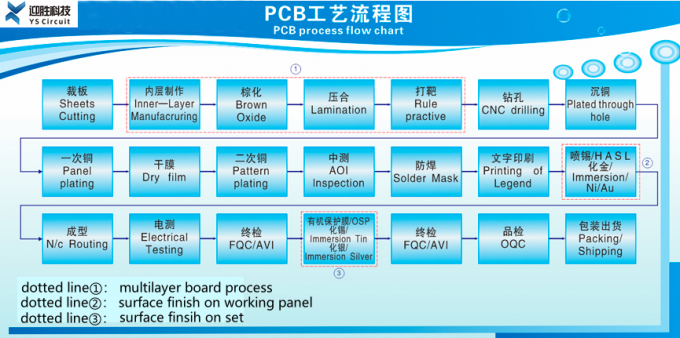

YScircuit Print Circuit Boards Production Process

PCB Stack UP

![]()

![]()

![]()

![]()

![]()

![]()

WHAT IS AN ALUMINUM PCB?

A PCB generally consists of three layers. A conductive copper layer at the top, a dielectric layer in between, and a layer of a substrate at the bottom. Standard PCBs have a substrate layer made of fiberglass, ceramic, polymers, or any other non-metal core. An ample amount of PCBs uses FR-4 as the substrate.

Aluminum PCBs use an Aluminum substrate. Instead of standard FR-4 as the substrate material.

Circuit Copper Layer

This layer transmits signals over the entire PCB board.

The movement of charged particles generates heat.

This heat is transferred to the Aluminum substrate. Which dissipates it efficiently.

Insulating Layer

This layer is also known as the dielectric layer.

It is made of materials that are poor conductors of electricity.

It absorbs the heat generated in the above layer. And transfer it to the Aluminum substrate below it.

Substrate

The substrate acts as a foundation for the PCB.

It firmly holds the components above it. By changing the characteristics of the substrate, the performance of PCB varies.

For example, a rigid substrate provides strength and durability to the PCB board.

While a flexible substrate opens up more design options.

The aluminum substrate is used in power electronics-based applications where high thermal dissipation is required.

Due to its good thermal conductivity, it keeps heat away from vital electronic components. Thus ensuring minimal circuit damage.

ALUMINUM PCBs MANUFACTURED AT YScircuit

YScircuit is one of the finest manufacturers of Aluminum PCBs.

To increase the overall performance of the product, they provide a thermal clad layer to the Aluminum PCB.

It dissipates heat in a highly efficient manner. For high power and tight tolerance based applications Aluminum Backed PCB is the perfect choice among project makers.

Considering parameters like the coefficient of thermal expansion, thermal conductivity, strength, hardness, weight, and cost. Aluminum plate is an ideal choice for your project. You can modify your PCB substrate. PCBWay offers different Aluminum plates like 6061, 5052, 1060, and many more.

ADVANTAGES OF ALUMINUM PCB

1. The heat dissipation capacity of Aluminum PCBs is far better than standard PCBs.

2. Aluminum PCBs provide more strength and durability. As compared to ceramic and fiberglass-based PCBs.

3. It seems ironic, but aluminum-based PCBs are lighter. As compared to standard PCBs.

4. Thermal expansion and contraction of PCB components get reduce by using Aluminum PCB.

5. PCBs made of Aluminum are environmentally friendly. It is non-toxic and recyclable. It does not create any harmful impacts on our planet.

6. The assembling process of Aluminum PCB is easy than that of standard PCB.

APPLICATIONS

1. They are used in Power supply devices like switching regulators, DC/AC converter, SW regulator.

2. In power modules, they are used in inverters, solid-state relays, and rectifier bridges.

3. In automobiles, they are used in an electronic regulator, ignition, power supply controller, etc.

4. They are the perfect choice for amplifiers. Balanced amplifier, audio amplifier, power amplifier, operational amplifier, high-frequency amplifier.

5. They are used in the transmitting and filtering circuit.

6. They are used to make the CPU board. And power supply of computers.

7. Electric motors require a high current for their operation. In industries, motor driver circuits use Aluminum PCB.

8. These are a popular choice for LED applications due to their energy-saving capability.