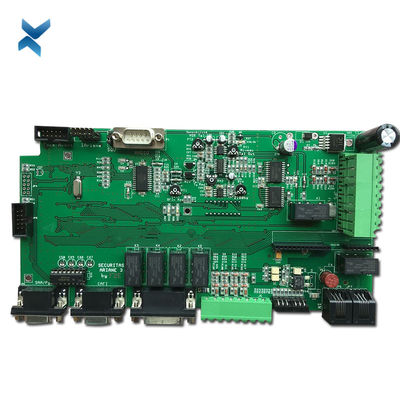

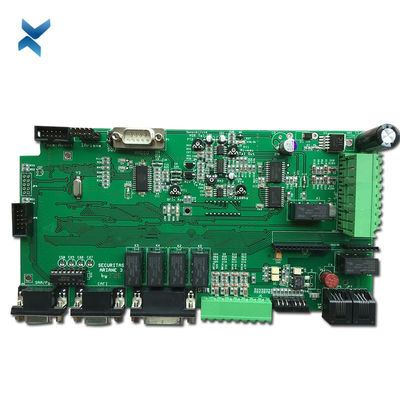

Industrial Architecture Turnkey PCB Assembly With HASL ENIG OSP Surface Treatment

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | YS-TK-0003 |

| Minimum Order Quantity | 1 piece |

| Price | 0.04-5$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | FR4+Components | Size | 18*9cm |

|---|---|---|---|

| Process | Immersion Gold/sliver/Assembly | Surface Finishing | HASL/HASL-LF/ENIG/OSP |

| Height | 5cm | Color | Green |

| Application | Architecture | Name | Architecture PCBA |

| High Light | Architecture Turnkey PCB Assembly,Industrial Turnkey PCB Assembly,HASL PCB Turnkey Assembly |

||

One-Stop Pcb Customized Pcba Board Assembly Design Service Boards For Architecture

YScircuit’s Turnkey PCB Assembly

If you like the idea of full turnkey services, a box build assembly may suit your needs even better. A box build assembly is a service that performs other necessary assembly work besides the assembly of the PCB itself.

Sometimes called systems integration, box build assembly services complete the steps remaining between the assembly of the PCB and the final product delivery.

Examples of steps covered can be as simple as placing the assembled circuit boards into an enclosure, or as complex as connecting the PCB assembly to a user interface.

Other assembly work involved in a box build includes:

- Sourcing and installing cables and wiring harnesses.

- Designing and installing sub-assembly components.

- Neatly packaging all assembled components into a custom enclosure.

- Loading software.

- Configuring systems.

- Packaging and labeling.

To perform such electromechanical assembly, businesses need dedicated staff, specialized equipment and a significant amount of production space that most small businesses can’t afford.

One of the most important services a box build assembly provides is inspection and testing of the finished boards.

Testing in a facility with a quality management system registered for ISO 9001 ensures the testing process is as rigorous and up-to-date as possible, so you don’t have to worry about expensive product failures and the resulting extensions to your project timeline.

![]()

| Capability | Standard |

| Certifications: | ISO 9001: 2015, AS 9100 Rev D, ISO 13485: 2016 |

| Lead Time: | 1-5 Days, As per the scheduled period |

| Parts procurement: | Full Turnkey, Partial Turnkey, and Knitted |

| Assembly Types: | Surface Mount (SMT), Thru-hole, Mixed Technology, Single and double-sided SMT/PTH. |

| Stencils: | Laser cut stainless steel and Nano-coating |

| Components: | Passive components smallest size 0201, Fine pitch components smallest size 8 Mils pitch. |

| Component packaging: | Reels, Cut Tape, Tube, and lose parts. |

| Inspection: | X-ray analysis, AOI, and Microscope to 20X |

| Solder Type: | Leaded and Lead-free/ RoHS compliant |

| Assembly Surface mount connectors: | Yes |

| Wave Soldering: | Yes |

| PCB Finish: | SMOB/HASL, Electrolytic gold, Electroless gold, Electroless silver, Immersion gold, Immersion gold, Immersion tin, and OSP. |

| Panelized PCB: | Tab routed, Breakaway tabs, V-scored and Routed + V scored |

| Rework: | BGA removal and replacement station, SMT IR rework station, and Thru-hole reworks station. |

| Design file format: | Gerber RS-27, 274D, Eagle and Auto CAD's DXF, DWG BOM, and Pick and place a file |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

![]()

![]()

![]()

![]()

![]()

FQA

1. What are the various types of turnkey printed circuit board assembly.

Surface mount (SMT), through-hole, mixed technology, single and double-sided SMT/PTH.

2. Do I have to physically meet the PCB manufacturing service provider to get a quote?

PCB manufacturing service providers now have an instant online quoting portal after receiving necessary files (c).

3. What are the advantages of full turnkey PCB assembly service?

Full turnkey PCB assembly service has several advantages including easy management, low or high-volume assembly, multiple services, quick lead times and more!

4. How much time does it take to get the deliveries after placing the order of turnkey PCB assemblies?

Our expected delivery time starts from the next day you are placing the order, which depends on the quantity and complexity of your turnkey PCB assembly requirements.

5. Can you provide immediate delivery for PCB turnkey assembly in case of an immediate need?

Yes, but the delivery time depends on the quantity you are placing with us.

6. Do you offer conformal coating services of turnkey PCB assemblies?

Yes, we offer conformal coating services. For more information, please contact us at sales@yscircuit.com

7. What are the factors that determine the cost of turnkey printed circuit board assembly service?

There are several factors including

- Board Quantity

- Type of printed circuit boards

- Number of SMT Pads

- Number of Through Hole

- Number of BGA components and Parts

- Complexity of printed circuit board assembly & more

8. What type of testing done on my PCB assemblies?

We do visual inspection, AOI inspection, x-ray inspection, functional testing and more!

9. Where do you export turnkey printed circuit board assembly?

We are exporting turnkey printed circuit board assemblies in USA, Europe (Germany, France, Italy, Spain, etc.), UK, Australia, New Zealand & more.

10. How can get a quick quote for turnkey PCB assembly?

All you need to do is, send question and BOM files, Gerber files, etc. to sales@yscircuit.com, feel free to ask in case if you have any questions or queries.