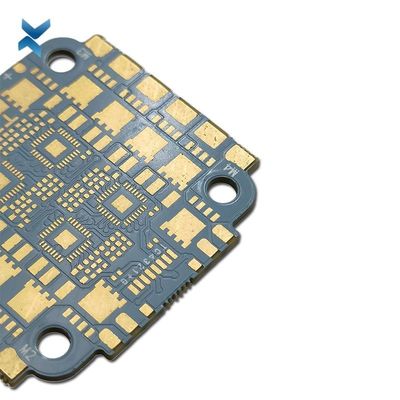

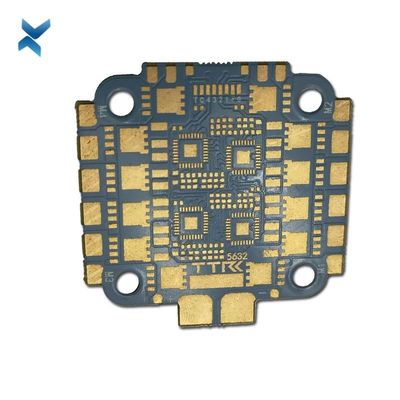

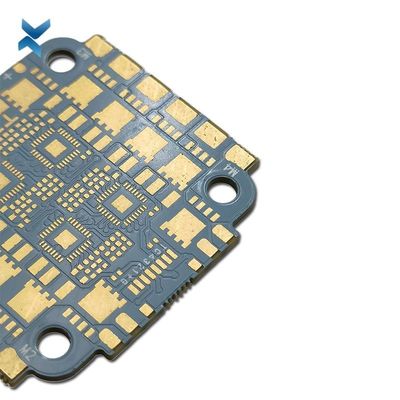

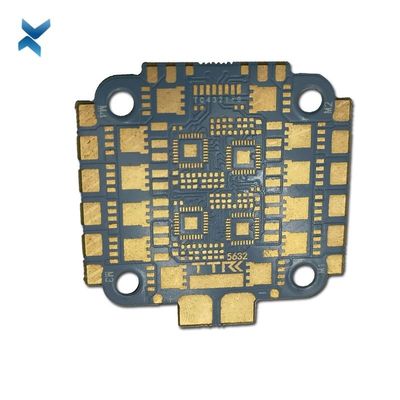

Multilayer Smart Isola PCB Circuit Board Assembly 4 Layers For Micro Wave Oven

| Place of Origin | Shenzhen |

|---|---|

| Brand Name | YScircuit |

| Certification | ISO9001,UL,REACH, RoHS |

| Model Number | YS-ISOLA-0003 |

| Minimum Order Quantity | 1 piece |

| Price | 0.04-5$/piece |

| Packaging Details | Foam cotton + carton + strap |

| Delivery Time | 2-8 days |

| Payment Terms | T/T,PayPal, Alibaba pay |

| Supply Ability | 251,000 square meter/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Isola | Size | According To Customer Request |

|---|---|---|---|

| Process | Immersion Gold/sliver | Surface Finishing | HASL/HASL-LF/ENIG/OSP |

| Layers | 4 Layers | Thickness | 0.3cm |

| Application | Micro-wave Oven | Name | Micro-wave Oven PCB |

| High Light | Isola PCB Circuit Board Assembly,Isola PCB 4Layers,Multilayer pcb circuit board assembly |

||

| Isola | 370HR |

| FR408HR | |

| IS680-300 | |

| FR406 | |

| IS620i | |

| IS410 | |

| P95/P25 | |

| GreenSpeed | |

| P96/P26 | |

| GETEK | |

| G200 |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

Don't hesitate send inquiry to info@yscircuit.com , YScircuit will be your good PCB Manufacturer.

![]()

If you want to find other high frequency PCB material .

You come to right place, Dupont PCB, Arlon PCB , Rogers PCB,Teflon PCB. etc.

Normally we have material in stock , If special Part number, We can buy material for you .

Donot wait anymore, send inquiry to sales@yscircuit.com , YScircuit will be your good PCB Manufacturer.

![]()

![]()

![]()

![]()

![]()

Have you been hoping to learn about Isola PCB?

Here we will be revealing to you everything possible about Isola PCB.

These include its uses, properties, features, quality testing, laminate material, quality certification, and more.

Please continue reading to become an Isola PCB expert.

1. What does Isola PCB Mean?

This printed circuit board is complex and fabricated making use of high-performance laminate materials.

It integrates resin constituents that are engineered in order to meet performance requirements that are demanding.

This PCB type is used in the majority of electronic equipment such as aerospace equipment and high-grade consumer electronics.

2. Types of Materials Used in Isola PCB

There are materials used in making Isola PCB. Some of them include

Prepreg

This term is associated with the PCB industry.

It is referred to as “previously impregnated.”

This is a dielectric material that offers electrical insulation, as well as other great features.

It is manufactured via fiberglass fabric infusion with resins that are uniquely formulated.

The resin incorporates distinct thermal, electrical, and physical features to the prepreg.

It is important in correcting the operation of the Isola PCB.

Copper Clad Laminates

This is made up of a prepreg laminated layer found on the two ends that have a thin layer of copper foil.

This lamination is achieved by compressing one or more copper and prepreg plies together under extreme heat, pressure, and vacuum conditions.

3. Constructing the Multilayer Isola PCB

Prepreg and CCL are utilized in fabricating multilayered Isola PCBs via complex operations that involve multiple processes that are usually repeated.

The copper surfaces of the laminate are etched.

This is to produce electronic circuits. Going forwards, assemble the laminates to form a multilayer structure via inserting one or more prepreg plies between each etched laminate.

Plating and holes drilling then follows the creation of electrical interconnections among PCB layers.

The Isola PCB that results is an interconnection gadget, where semiconductors and other parts are mounted.

Isola PCB Applications

The laminate and prepreg materials of Isola PCB can be applied in different equipment and advanced electronic which includes:

- Aerospace applications

- Military electronic applications

- Industrial equipment applications

- High-end consumer electronics

- Network and other communications devices

- Automotive applications

- Medical equipment applications

4. What Material is used in Making Isola PCB’s Resin System?

Isola PCB makes use of no-flow prepregs, which are polyimide-based for PCB applications requiring high temperatures.

They make use of a polyimide, retardant resin system, which is great for applications requiring superior performance and thermal properties.

The prepreg materials of the Isola apply a polyimide blend and thermoplastic resin, which are fully cured without making use of Methylenedianiline (MDA).

This then leads to polymers that have a high Tg, which lacks the problems of brittleness and low initial bond strength.

Therefore the resin system of Isola PCB is much better compared to the resin structure of conventional thermoset polyimide.

5. Features of the Isola Prepreg Materials

Below are some of the major features of the materials of Isola PCB:

- Sustains the strength of the bond at an elevated temperature

- Halogen-free options present

- Higher thermal performance

- Reduced delamination as a result of machining

- Enhanced processing as a result of less brittleness

- Resin system lasts long

YS Service:

Next day shipping service, can finished prototype within 24 hours.